The Duty of Technology in Modern Welding Inspection Madison Practices

The Duty of Technology in Modern Welding Inspection Madison Practices

Blog Article

Recognizing the Basics of Welding Examination to Make Sure Quality and Security

In the realm of modern-day engineering, welding examination stands as a cornerstone for making certain both the quality and security of structural developments. What are the subtleties of these evaluation approaches that make them important for keeping structural stability?

Relevance of Welding Inspection

In the world of commercial construction, the significance of welding evaluation can not be overstated. Welding inspection plays a crucial role in ensuring the honesty, safety and security, and long life of bonded structures (Welding Inspection Madison).

The process of welding naturally entails complicated variables, including temperature, product residential or commercial properties, and environmental conditions, every one of which can affect the high quality of the weld. A detailed examination recognizes issues such as splits, porosity, and insufficient blend, which can jeopardize the stamina and dependability of the weld. By identifying these concerns early, corrective actions can be taken, therefore reducing the risk of failing and connected costs.

Additionally, welding examination adds to regulative conformity, as lots of industries are controlled by rigorous security requirements and guidelines. Failing to follow these guidelines can result in financial fines and lawful obligations. Eventually, welding examination not just safeguards physical structures but additionally secures human lives and supports industry reputations.

Key Welding Assessment Approaches

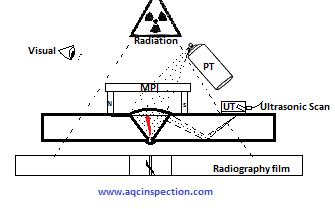

Although welding evaluation is crucial to ensuring the top quality and safety of bonded frameworks, it is the particular techniques utilized that establish the effectiveness of the evaluation process. Trick welding examination approaches can be broadly categorized into non-destructive testing (NDT) and damaging screening. Non-destructive screening approaches such as aesthetic inspection, ultrasonic testing, radiographic screening, magnetic fragment screening, and fluid penetrant screening are largely used to review the buildings of a weld without causing damage. Visual evaluation is commonly the first step, involving an extensive assessment of the weld's surface area for defects like cracks or porosity.

Radiographic and ultrasonic testing are advanced strategies that enable inspectors to assess the internal integrity of the weld. Ultrasonic screening utilizes high-frequency sound waves to spot suspensions, while radiographic testing uses X-rays or gamma rays to generate a picture of the weld's inside. Magnetic fragment testing and fluid penetrant testing are surface evaluation methods made use of to situate surface area and near-surface defects. On the other hand, damaging testing methods entail literally damaging or cutting the weld to evaluate its mechanical buildings. These extensive inspection methods make sure that welds satisfy sector requirements and safety needs, thus ensuring architectural integrity and efficiency.

Function of Qualified Examiners

Certified assessors play an essential role in the welding inspection procedure, making sure that all welds conform with stringent market criteria and security regulations. Their knowledge is crucial in recognizing defects or irregularities that may jeopardize the structural honesty of a weld. By diligently checking out each weld, licensed inspectors help protect against prospective failures that might cause dangerous accidents or pricey repairs.

To end up being qualified, inspectors must undertake extensive training Read Full Article and screening, which acquaints them with various welding techniques, products, and testing techniques. This comprehensive expertise enables them to assess weld quality efficiently and make informed judgments concerning their security and integrity. Furthermore, qualified assessors are efficient in analyzing plans and specifications, guaranteeing that the welding work straightens with the job's style needs.

An important component of their role is to record their findings thoroughly, offering an in-depth document of the examination procedure. Their contribution is crucial in maintaining high degrees of high quality and safety and security in welding procedures.

Tools Made Use Of in Welding Inspection

Welding examiners rely upon a range of specialized tools to execute their responsibilities effectively, ensuring each weld satisfies the essential criteria. Among these tools, aesthetic evaluation help like multiplying glasses and mirrors are essential, allowing inspectors to closely take a look at welds for surface issues such as cracks, this contact form porosity, and undercut. Calipers and fillet weld gauges are important for measuring weld measurements to verify conformity with layout specifications.

Advanced tools extend past visual help, including non-destructive screening (NDT) equipment. Ultrasonic testing gadgets are essential in spotting subsurface problems, using audio waves to expose interior discontinuities without endangering the weld's integrity. Radiographic screening utilizes X-rays or gamma rays to record images of a weld's interior, highlighting possible defects.

Magnetic fragment testing is another crucial tool, specifically for finding surface and near-surface interruptions in ferromagnetic materials. By applying electromagnetic fields and ferrous fragments, inspectors can determine flaws that could or else be undetectable.

Dye penetrant examination is frequently utilized for non-ferrous products, supplying a contrast-enhanced aesthetic look for surface-breaking defects. Welding Inspection Madison. With each other, these tools allow welding inspectors to comprehensively analyze weld high quality, ensuring safety and integrity in different applications throughout sectors

Ensuring Structural Stability

Welding treatments should stick to well established standards and codes, such as those specified by the American Welding Society (AWS) or the International Organization for Standardization (ISO) These guidelines make certain that the welds can withstand environmental aspects and operational tensions. Qualified and accredited welders play a vital role in this procedure, as their expertise makes sure that techniques are applied properly, decreasing defects such as cracks, porosity, and incomplete blend.

Post-weld examination is an additional vital element of verifying architectural integrity. Non-destructive screening (NDT) methods, consisting of ultrasonic testing and radiographic testing, are employed to find subsurface problems without endangering the welded framework. These evaluations verify that the welds satisfy the needed top quality criteria, giving assurance of their resilience and integrity. Eventually, making certain structural honesty in welding not just safeguards human lives but additionally secures financial investments and enhances the longevity of engineered structures.

Final Thought

The fundamentals of additional hints welding inspection are vital for preserving the quality and safety and security of bonded structures. The usage of specialized tools additionally enhances the examination process, ultimately safeguarding human lives and lengthening the life-span of welded buildings.

Welding assessment plays an important role in guaranteeing the honesty, safety, and longevity of bonded structures.Although welding assessment is crucial to making certain the quality and security of bonded structures, it is the details techniques employed that figure out the performance of the inspection process. Secret welding examination methods can be broadly categorized right into non-destructive testing (NDT) and damaging testing.Licensed examiners play a critical function in the welding examination procedure, making sure that all welds comply with strict market requirements and security laws.The principles of welding inspection are necessary for keeping the top quality and safety of welded structures.

Report this page